Making Syrup (2011)

The syrup campaign marks the passage of another year for me as it comes regularly, requires my participation and excites all the senses . . . waiting anxiously for the boiling froth to rise over the rim, watching for the final skimmings to remove, a feeling of insecurity about timing to take it up. All these and more emotions flood as the sweet aroma evokes nostalgic images in my soul and an anticipation of a product I will enjoy for the coming year. Given the importance to me, I have recorded here notes that will allow me to relive the day. I hope that others might perhaps enjoy the day vicariously, but I quickly admit that I do not hold myself out to the public as an expert, and sincerely acknowledge the many other ways of making syrup while not thinking mine hold advantages over them. For context, recall that I do not make syrup commercially and thus my protocols are geared to my personal abilities, resources, enjoyment and preferences. In other words, this is a summary of the year that I may examine when I plan next syrup season.As an annual milestone, syrupmaking provides an opportune time to look over the previous year, particularly as it relates to syrup. Thus, the immediately following few paragraphs run in this personal vein and the general reader will wish to skip ahead to Slide 5.

Paramount, I note with sadness the untimely death of

our beloved Belle, who is shown (Slide

1) with daughter Elizabeth in the cane patch on 2004-08-06. All of our dogs

have been better than we deserve and certainly Belle's passing left a gaping hole

in my heart. We will never forget her devotion, enthusiasm, and joie de

vivre. She took us to the next level. RIP, Belle: we'll be along

sometime--you might expect first to see Buttley. For those who haven't met

Buttley (nearly 13 yo), note her standing in this photo (made alongside Slide 1). A young Priss, also shown,

and officially down to less than 100 lbs. now, still enjoys playing pat-a-cake

with me, but my trademark pink hat (appropriated from Nedra!) has long since

succumbed to Father Time. Making syrup or not, our interactions with the dogs are

priceless and I observe with fascination the adaptations they so readily make. At

one moment, Priss is still a huge baby; at the next if she senses danger, she

stands tall and chews menacingly on a frightening snarl with every hair erect. .

. . but, really that's tangential. Looking to the future, we await seeing our new

grandpuppy, Gabby (shown here on Granny Della's bed), playing in the cane

patch.

Paramount, I note with sadness the untimely death of

our beloved Belle, who is shown (Slide

1) with daughter Elizabeth in the cane patch on 2004-08-06. All of our dogs

have been better than we deserve and certainly Belle's passing left a gaping hole

in my heart. We will never forget her devotion, enthusiasm, and joie de

vivre. She took us to the next level. RIP, Belle: we'll be along

sometime--you might expect first to see Buttley. For those who haven't met

Buttley (nearly 13 yo), note her standing in this photo (made alongside Slide 1). A young Priss, also shown,

and officially down to less than 100 lbs. now, still enjoys playing pat-a-cake

with me, but my trademark pink hat (appropriated from Nedra!) has long since

succumbed to Father Time. Making syrup or not, our interactions with the dogs are

priceless and I observe with fascination the adaptations they so readily make. At

one moment, Priss is still a huge baby; at the next if she senses danger, she

stands tall and chews menacingly on a frightening snarl with every hair erect. .

. . but, really that's tangential. Looking to the future, we await seeing our new

grandpuppy, Gabby (shown here on Granny Della's bed), playing in the cane

patch.

Completion of the Syrup Shed was a big 2011 accomplishment

for us. Actually, "completion" refers to the original plan, so more work is still

coming. It is small building (20 x 24, with about a quarter cut out for an open

porch, where grinding takes place; another quarter is taken up by the kettle).

The remainder has to accomodate several space-consuming activities (e.g., as a

Honey House, Crush Pad, Food Preparation Center). We began the Syrup Shed in early

2004, very modestly, laying it out with a homemade tripod and plumb bob (Slide 2). (Our permit was only issued in July, 2004, but we began

earlier--digging a hole and even laying steel and PVC in it does not require a

permit.) I completed the building with the wiring of the point-source

heater, installation of a flow regulator and sink weeks before the 2011 syrup

campaign. Seven-plus years is a long time to work on a little shed, but we did

use it even before the walls were erected (Syrupmaking 2004). In brief, we were on a pay-as-you-go plan. When

time wasn't limiting, money was, and vice versa. . . . and essentially,

often we had to convert our time to money (e.g., by recycling cabinets). We also

made the conscious choice to put our own mark on the building (e.g., by assisting

in cutting, sawing, and planing our own cherrywood for one wall). It would be

dishonest, though, if I didn't admit up front that I was painfully slow on jobs I

had never done before (e.g., building a furnace, laying blocks), even not taking into account the inefficiency

of working alone on some projects. Of course, one can't stop and work solely on a

hobby and a lot of our time this past year was involved in maintenance (e.g., here: pond renovation (by Jimmy Drawdy), here: equipment care, here: landscaping, here: forest management (by Joe Matthews) and the list goes on). A

long-time plan for certification in Georgia's Centennial Farm program was also

realized and we hope that by next syrup season, we will be

certified in the forest stewardship program. So far, retirement has not fulfilled

its promise of a boring time.

Completion of the Syrup Shed was a big 2011 accomplishment

for us. Actually, "completion" refers to the original plan, so more work is still

coming. It is small building (20 x 24, with about a quarter cut out for an open

porch, where grinding takes place; another quarter is taken up by the kettle).

The remainder has to accomodate several space-consuming activities (e.g., as a

Honey House, Crush Pad, Food Preparation Center). We began the Syrup Shed in early

2004, very modestly, laying it out with a homemade tripod and plumb bob (Slide 2). (Our permit was only issued in July, 2004, but we began

earlier--digging a hole and even laying steel and PVC in it does not require a

permit.) I completed the building with the wiring of the point-source

heater, installation of a flow regulator and sink weeks before the 2011 syrup

campaign. Seven-plus years is a long time to work on a little shed, but we did

use it even before the walls were erected (Syrupmaking 2004). In brief, we were on a pay-as-you-go plan. When

time wasn't limiting, money was, and vice versa. . . . and essentially,

often we had to convert our time to money (e.g., by recycling cabinets). We also

made the conscious choice to put our own mark on the building (e.g., by assisting

in cutting, sawing, and planing our own cherrywood for one wall). It would be

dishonest, though, if I didn't admit up front that I was painfully slow on jobs I

had never done before (e.g., building a furnace, laying blocks), even not taking into account the inefficiency

of working alone on some projects. Of course, one can't stop and work solely on a

hobby and a lot of our time this past year was involved in maintenance (e.g., here: pond renovation (by Jimmy Drawdy), here: equipment care, here: landscaping, here: forest management (by Joe Matthews) and the list goes on). A

long-time plan for certification in Georgia's Centennial Farm program was also

realized and we hope that by next syrup season, we will be

certified in the forest stewardship program. So far, retirement has not fulfilled

its promise of a boring time.

The big improvement of work flow in our syrupmaking was the

joint result of (a) removing a large fig tree that was overtaking my Syrup Shed

and blocking through-traffic by the pomace side of my mill and (b) the purchase

of this little Kubota L3800 (Slide 3). In one fell swoop, I moved from pitchforking pomace

onto a nearby trailer to simply and easily pushing it out of the way. Many thanks

to Nedra, who had petitioned me for years to purchase a reliable tractor. She had

observed often that I spent more time working on my old tractor than working it.

(The situation was exacerbated by my failure as a mechanic.) In my family since

it was new, the old 1956 640 Workmaster has returned to the farm waiting perhaps

until time catches up with me. Prissy is, incidentally, doing what Prissy does,

that is, snooping. One can almost hear the wheels spinning in her head: "this

stalk came from the 3d row, about 10 feet down. . . . smells like the brix is

~17%. Dad didn't trim the end well enough on this one. Yada. Yada. Yada." GSDs

are too smart for people like me; I should stick to Akitas.

The big improvement of work flow in our syrupmaking was the

joint result of (a) removing a large fig tree that was overtaking my Syrup Shed

and blocking through-traffic by the pomace side of my mill and (b) the purchase

of this little Kubota L3800 (Slide 3). In one fell swoop, I moved from pitchforking pomace

onto a nearby trailer to simply and easily pushing it out of the way. Many thanks

to Nedra, who had petitioned me for years to purchase a reliable tractor. She had

observed often that I spent more time working on my old tractor than working it.

(The situation was exacerbated by my failure as a mechanic.) In my family since

it was new, the old 1956 640 Workmaster has returned to the farm waiting perhaps

until time catches up with me. Prissy is, incidentally, doing what Prissy does,

that is, snooping. One can almost hear the wheels spinning in her head: "this

stalk came from the 3d row, about 10 feet down. . . . smells like the brix is

~17%. Dad didn't trim the end well enough on this one. Yada. Yada. Yada." GSDs

are too smart for people like me; I should stick to Akitas.

Yellow jackets are part and parcel of making syrup. They swarm around the mill, the juice, and the pomace. I particularly remember the aggravation they presented at Edgar Bennett's once. (Edgar married my grandfather's first cousin, so inherited the syrupmaking tradition from Uncle Bill ). Without a hint of hyperbole, I say that I have never seen anything like the hundreds around my grinding this year; indeed, nothing I have seen could even be compared with it. As a beekeeper, I am not a stranger to stings, but, of course, I'd prefer not to accrue more experience. The only upside was that Ken Christison confidently told me that they would not bother me. Wrong, Ken. Perhaps I should explain: the upside is Ken's being wrong--a first. Anyhow, it came down to me against the yellow jackets. I devised a plan, viz., I would spread out a pile of pomace (out in the back, removed from my work) and liberally soak it with sugar water, then zap the lot of them with a tank mix of sevin and malathion. (I usually use no insecticides, but keep a couple of fresh bottles just for situations as described.) They really came in for the bait, like bees around a corn-syrup-feeding barrel. I sprayed, and of course, with deadly results. I congratulated myself, imagining that they would continue to swarm onto and consume my deadly concoction. I was wrong: foraging stopped immediately at the poisoned site. Not a jacket to be seen. The field force shifted over to my workplace. How could they know and communicate the results--did they do it on-site or did they return to the nest? Social wasps similar to yellow jackets have an uncanny ability to recognize each other and danger. Honey bees respond very quickly to danger and an alerted forager emits a stop signal that lasts a mere tenth of a second and interferes with a dancer who is directing foragers to a dangerous site. How cool is that? Anyhow, the jackets defeated me that day and I resorted to the use of my inspector jacket and used a shop vacuum cleaner from time to time to diminish the numbers around the ends of the cane I was picking up to mill. As implied, removing and killing the jackets by vacuum had no effect on other foragers, which continued to come in droves. So, at a minimum, it seems that the jackets did not learn by observation to avoid a location; they had to get the signal somehow from an aggrieved sibling. The jackets and I had a rematch on 2012-01-07 and I won. I was using my tractor to move brush from around a fallen tree when I disturbed their nest. Suffice it to note that I nearly ruined my glasses because one got under them (more dangerous than humorous, an insect sting to the eye can result in loss of vision). I filled the bucket of my front-end loader with the referenced tank mix, delivered it to site and mixed with the soil. End of problem. (FYI, both sevin and malathion are recommended for use in soil drenches.)

When contructing the Syrup Shed, I realized that steam management

could be a problem. I also realized that there would some turbulence, but naively

dismissed its importance, and implicit in my treatment was laminar flow. As a

solution, I installed an industrial fan (Multifan 2E30, > 2000 cfm). At full

speed, this fan does indeed remove the steam. Unfortunately, at full

speed, it is uncomfortably noisy. . . . thus, back to the drawing board. I

considered a stainless steel hood, but the pocket-book issues are difficult to

overcome; anyhow, I'd like to keep the area above the kettle open for esthetics.

Instead, I installed aluminum tracks that are used in greenhouses to attach

plastic (Slide 4, taken from the kettle's perspective). Again, though,

I misjudged and left a passage open and some steam did escape; I've purchased

additional track and will make the enclosure complete before next season.

Although it appears to be jerry-rigged, it is not a bad solution in my opinion.

It takes perhaps 30 min to install the plastic (2-mil painter's drop cloth) and

is inexpensive, both monetarily and environmentally. (Incidentally, given my poor

record in making predictions inside the little nominal 10 x 10 ft kettle area, I

have become very understanding when weathermen are imprecise on 5-day

forecasts.)

When contructing the Syrup Shed, I realized that steam management

could be a problem. I also realized that there would some turbulence, but naively

dismissed its importance, and implicit in my treatment was laminar flow. As a

solution, I installed an industrial fan (Multifan 2E30, > 2000 cfm). At full

speed, this fan does indeed remove the steam. Unfortunately, at full

speed, it is uncomfortably noisy. . . . thus, back to the drawing board. I

considered a stainless steel hood, but the pocket-book issues are difficult to

overcome; anyhow, I'd like to keep the area above the kettle open for esthetics.

Instead, I installed aluminum tracks that are used in greenhouses to attach

plastic (Slide 4, taken from the kettle's perspective). Again, though,

I misjudged and left a passage open and some steam did escape; I've purchased

additional track and will make the enclosure complete before next season.

Although it appears to be jerry-rigged, it is not a bad solution in my opinion.

It takes perhaps 30 min to install the plastic (2-mil painter's drop cloth) and

is inexpensive, both monetarily and environmentally. (Incidentally, given my poor

record in making predictions inside the little nominal 10 x 10 ft kettle area, I

have become very understanding when weathermen are imprecise on 5-day

forecasts.)

Over the years, we have followed several protocols for making

syrup (e.g.,expressing the juice and evaporating it to syrup in one linear

sequence, or expressing the juice and storing it cold with syrupmaking the

following day, or expressing the juice and processing it through skimming, then

finishing the syrup the next day). This year, I cut, washed and squeezed enough

POJ cane for ~12 gallons of frozen juice (2011-11-18). This beautiful cane

deserves yet another photo (Slide 5). (Incidentally, the filtered juice is

frozen in recycled milk jugs and thus does not impose an environmental

burden.

Over the years, we have followed several protocols for making

syrup (e.g.,expressing the juice and evaporating it to syrup in one linear

sequence, or expressing the juice and storing it cold with syrupmaking the

following day, or expressing the juice and processing it through skimming, then

finishing the syrup the next day). This year, I cut, washed and squeezed enough

POJ cane for ~12 gallons of frozen juice (2011-11-18). This beautiful cane

deserves yet another photo (Slide 5). (Incidentally, the filtered juice is

frozen in recycled milk jugs and thus does not impose an environmental

burden.

2011 will be remembered for the historical

hot and dry conditions in Tallahassee. It was the second driest year on

record and followed two years of below-average precipitation. We received almost

no rain from the end of April until the middle of June. (Would you not know,

though, that there was higher-than-average rainfall during veraison for my Blanc

du Bois grapes?) The summer (June-August) was the hottest on record, breaking the

record set in 2010. A new high temperature record also was set. Although I

planted enough cane to make 2-3 kettles of syrup on an average year, it was

obvious that my non-irrigated cane was a failure. Indeed, I had one 30-foot

stretch of plant cane that came up and died when it reached 8-10 inches tall.

Thus, I had visited Richard Harrison on 2011-11-11 (i.e., before I ground the POJ

for frozen juice, above) and bought enough cane to finish me up. Actually, I had

intended to visit Richard later but an unusual cold snap--22 F the

12th--altered my plans. Richard's cane was also affected by drought,

but CP 57-603 (Slide 6) did well relatively. Closer views of this cane

in the truck and during cleaning are also provided. Richard is our resident

expert on cultivars for syrup production, and he has abundant enthusiasm for CP

57-603 (which is widely grown in the world, though not in the U.S.). He has

indicated that one strain returns from the stubble well, has high brix, and makes

good syrup. On my limited experience, I liked it also.

2011 will be remembered for the historical

hot and dry conditions in Tallahassee. It was the second driest year on

record and followed two years of below-average precipitation. We received almost

no rain from the end of April until the middle of June. (Would you not know,

though, that there was higher-than-average rainfall during veraison for my Blanc

du Bois grapes?) The summer (June-August) was the hottest on record, breaking the

record set in 2010. A new high temperature record also was set. Although I

planted enough cane to make 2-3 kettles of syrup on an average year, it was

obvious that my non-irrigated cane was a failure. Indeed, I had one 30-foot

stretch of plant cane that came up and died when it reached 8-10 inches tall.

Thus, I had visited Richard Harrison on 2011-11-11 (i.e., before I ground the POJ

for frozen juice, above) and bought enough cane to finish me up. Actually, I had

intended to visit Richard later but an unusual cold snap--22 F the

12th--altered my plans. Richard's cane was also affected by drought,

but CP 57-603 (Slide 6) did well relatively. Closer views of this cane

in the truck and during cleaning are also provided. Richard is our resident

expert on cultivars for syrup production, and he has abundant enthusiasm for CP

57-603 (which is widely grown in the world, though not in the U.S.). He has

indicated that one strain returns from the stubble well, has high brix, and makes

good syrup. On my limited experience, I liked it also.

As mentioned, Richard indicated that the juice of CP 57-603 has a high brix. I also obtained a high value, 19.6%, with the juice from Richard's cane. This year, the brix of my POJ and of my CP 67-500 was 15.8% and 16.0%, respectively, perhaps a little lower than it is most years. (My values for brix are always obtained from juice expressed from several whole stalks, the larger the sample, the better. I also note that I checked the calibration of my refractometer and thus have confidence in these values.) Of course, one year's measurements are enough to get hopes up, but not enough to make a conclusion. With that caveat, I noted that I did not see red rot in the CP 57-603 that I cut, but it is present in other varieties and that the juice requires less straining compared with POJ and CP 67-500. On the negative side, it has a tendency to break in the mill. At the other extreme, I ground a little Cayana this year. While the other cultivars have struggled, I have been unable to get rid of a little Cayana that contaminates my cane patch. It's a lot like rebar--small bore, hard, dry, and the brix is low (12% this year). However, it does have survival genes and should be maintained.

The importance of seemingly small differences in juice brix is better understood by quantitative examination. Assume that the final syrup has a brix of 76% (= boiling point of 226.2 F), and accept 1.061, 1.074, 1.079 and 1.382 as the specific gravities for brixes, respectively, of 15, 18, 19, and 76 (values from Deerr, N (1911) Cane Sugar. Norman Rodger Altrincham (Manchester)). Thus, at 100% yield, it takes 6.6 gallons of 15%-brix juice to produce a gallon of syrup, but only 5.1 gallons of 19%-brix juice, a 29% increase with the lower-brix juice. Said differently, 28% more water has to be removed from the lower-brix juice to make the syrup. Obviously, higher yield, less time, and less energy are compelling. Calculations along this line also show me that I lose too much syrup in processing. Specifically, this year, I began with 55 gallons of juice, brix =18.2% and 100% theoretical yield would have been about 10 gallons, but the actual yield was only 7.5 gallons. Some losses are unavoidable, e.g., skimming, and I knew already I was losing too much, especially in the filtering cloths. Before next year, I will think through my protocol. My top priority is, of course, making syrup that I like, and I only use a case or so a year. But, since I have the work invested, there is an incentive to improve the yield. (btw, I also have this mental conflict in the making of some wines--each time I rack, I lose some, but each time I rack I might get a better wine.)

Within bounds, I make syrup when I am in the mood.That was at 0610

on 2011-11-22. Within 10 min, I had frozen blocks of

Within bounds, I make syrup when I am in the mood.That was at 0610

on 2011-11-22. Within 10 min, I had frozen blocks of  juice

in my nominal 50-gallon stainless steel drum and starting grinding (Slide 7). As usual, I filtered the juice through two ss

screens at the mill and carried out a second filtration through diaper into the drum in the usual

manner (5-gallon buckets). By 0941, I was ready to start (Slide 8) the furnace. Note the floating ice.

juice

in my nominal 50-gallon stainless steel drum and starting grinding (Slide 7). As usual, I filtered the juice through two ss

screens at the mill and carried out a second filtration through diaper into the drum in the usual

manner (5-gallon buckets). By 0941, I was ready to start (Slide 8) the furnace. Note the floating ice.

As a small-time syrupmaker, I have difficulty in growing just the right amount of cane for one round. Except for this year, I have always had excess cane, which I have cut and discarded. These floating blocks of ice suggests a different approach, viz., to freeze 20-30 gallons of juice and use the blocks of frozen juice not only for cooling, as here, but for concentrating the juice (cyroextraction). In brief, I would continue to grind until my cane is exhausted and discard one-by-one the partially melted blocks to make space for fresh juice. In this way, my excess cane would not simply be lost and I should start cooking with a higher brix with all the advantages discussed earlier. (An advantage of this approach might be uniquely mine as I keep a chest freezer for freezing honey supers (to kill wax moth eggs and small hive beetles) and there is ample empty space in it during the syrup campaign.)

There was a time when I could work from 6:30 am

until 9:30 pm on concrete in the sun at a real service station (no air rachets

for tire changing, manually operated jacks . . .). There was a time when I could

trudge along "forever" with an 80-lb mortar base plate on my back. Even a few

years ago, I dismissed a concern for efficiency. However, past the middle of my

7th decade, I must look for shorter stretches of hard work, especially

since I process the cane alone, and once begun, must continue. At the expense of

redundancy, it is not hard work that I want to avoid, but hard work for hours on

end when becoming reckless could be dangerous (the mill itself, the boiling

juice, &c.). I tend to be a morning person and ideally would like to finish

by 2 pm. Freezing a little juice ahead certainly does spread the job out, but the

primary purpose for my keeping juice cool is my hypothesis that at least some of

the dregs in syrup comes from microbial activity in juice that is kept warm for

long periods. Freezing  a lot of juice, as mentioned in the previous paragraph, will,

of course, transfer a part of the work to an earlier day as would the use of

large-bore juicy cane (it is another story, but I do wish I could grow Home Green

well). As a means of understanding how I spend my time (and because I like

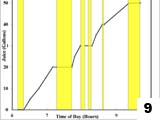

numbers), I recorded my activities during juice preparation. Slide 9 indicates the accumulation of juice from my starting

time of 0610 until 0941, when I was ready to fire the furnance (y-axis=juice

accumulation (gallons); x-axis=time (h)). The vertical yellow bars indicate down

time, when no juice was being accumulated. Overall, my actual grinding time was

144 min (& were I working with another, this would be the total time). Some

down time was purely unnecessary (e.g., determining yield and brix of Cayana),

and some was unavoidable (e.g. a short break). Overall, with altering some

procedures (esp filter management), 37 min could be saved. For a detailed

analysis, click here.

a lot of juice, as mentioned in the previous paragraph, will,

of course, transfer a part of the work to an earlier day as would the use of

large-bore juicy cane (it is another story, but I do wish I could grow Home Green

well). As a means of understanding how I spend my time (and because I like

numbers), I recorded my activities during juice preparation. Slide 9 indicates the accumulation of juice from my starting

time of 0610 until 0941, when I was ready to fire the furnance (y-axis=juice

accumulation (gallons); x-axis=time (h)). The vertical yellow bars indicate down

time, when no juice was being accumulated. Overall, my actual grinding time was

144 min (& were I working with another, this would be the total time). Some

down time was purely unnecessary (e.g., determining yield and brix of Cayana),

and some was unavoidable (e.g. a short break). Overall, with altering some

procedures (esp filter management), 37 min could be saved. For a detailed

analysis, click here.

Recall that the furnance was fired at ~0940; by 1010 the juice had reached 135F and I treated with invertase in the usual manner. At 1040, the burner was turned back on and at 1055, the juice was 185F and I started skimming.

As discussed in several essays and in the previous paragraph, I treat my juice with invertase to hydrolyze a fraction of the sucrose. The resulting hexoses are more soluble and thus "sugaring" in the pure sugar-cane syrup is avoided. The goal is to hydrolyze only a limited amount of the sucrose, viz. to lower the sucrose content from typically 80-85% of total sugar to ~70% (example of several analyses conducted over the years). Insufficient hydrolysis and the aim of avoiding crystallization is not met and too much hydrolysis results in darkening or even off-flavor. (For an otherwise unavailable 32-MB ppt on use of invertase as a processing aid in making syrup, click here.) My method of using invertase has three disadvantages: (a) it adds 30 min to the day, but I usually use this time for a shower and change into fresh clothes. I like to be properly dressed when I call "Syrup!" (b) the 30-min incubation is a dangerous time, IMHO, as the conditions are very good for microbial mischief. It is not practical with a kettle to heat to 165F for sterilization, then drop to 135F for invertase incubation, but juice sterilization by use of UV is an option I may (or may not) implement. (c) production of hexoses before cooking means that the syrup will be darker, undeniably, via the Maillard Reaction, which is speeded by heating. As the old-timers suggested, it would be preferrable to separately conduct hydrolysis on semi-syrup. Said differently, it is preferrable to add hexoses at the end of cooking than at the beginning. Since my syrup is reasonably light (samples from this cooking), I may let well enough alone, or I may not. It would clearly be an order of magnitude easier to hydrolyze 100% of sucrose in a small sample and add it to untreated nascent syrup to achieve the desired portion of sugars.

At 1100, the juice hit 200F and I cut back the burner; at 1103, the

juice hit 205F and I cut the burner more. I skimmed, gradually moving to a gentle

boil (Slide 10, flue temp = 650F) until 1205, when I poured the

heat to it (flue temp <1400F).

At 1100, the juice hit 200F and I cut back the burner; at 1103, the

juice hit 205F and I cut the burner more. I skimmed, gradually moving to a gentle

boil (Slide 10, flue temp = 650F) until 1205, when I poured the

heat to it (flue temp <1400F).

The juice was

self-skimming by 1325 (2.5 MB Video Clip 1 -- all videos are .mov files; a close-up view is

shown in 1.4 MB Video Clip 2 whereas a static version taken later is

displayed in Slide 11). By 1405, the heat had been decreased and the

diapers replaced for the first time. 1.8 MB Video Clip 3 shows the appearance of the boiling syrup at

1421 and 3.0 MB Video Clip 4 shows the appearance at 1435.

The juice was

self-skimming by 1325 (2.5 MB Video Clip 1 -- all videos are .mov files; a close-up view is

shown in 1.4 MB Video Clip 2 whereas a static version taken later is

displayed in Slide 11). By 1405, the heat had been decreased and the

diapers replaced for the first time. 1.8 MB Video Clip 3 shows the appearance of the boiling syrup at

1421 and 3.0 MB Video Clip 4 shows the appearance at 1435.

Seeing the end

in sight, I changed the diapers again and continued to skim incessantly (Slide 12, taken at 1443), taking advantage of a nearby floor drain and potable water spray. Of course, at

this stage--when the situation moves quickly--I obsess about density measurements. 3.6 MB Video Clip 5 was taken at 1446 and 3.0 MB Video Clip 6 was taken at 1450.

Seeing the end

in sight, I changed the diapers again and continued to skim incessantly (Slide 12, taken at 1443), taking advantage of a nearby floor drain and potable water spray. Of course, at

this stage--when the situation moves quickly--I obsess about density measurements. 3.6 MB Video Clip 5 was taken at 1446 and 3.0 MB Video Clip 6 was taken at 1450.

I called syrup

at 1458 & 34.5 Baume (measured hot, of course) (Slide 13), and fitted my insulating bonnet over the bottler; the

temperature of the last bottle was 187F.

I called syrup

at 1458 & 34.5 Baume (measured hot, of course) (Slide 13), and fitted my insulating bonnet over the bottler; the

temperature of the last bottle was 187F.

At the end of the day, I rechecked my propane supply, realizing the gauges provide only a rough measure. Still and all, over the years, I observe that I use about 12 gallons of propane per kettle (this year, 7.5 gallons of syrup, which is a bit higher than earlier times because I started with higher brix juice.) Of course, heat is lost up the flue, from the furnace, and an indeterminate amount of heat is used for the lost syrup (in skimmings, filtering, etc.). This usage is in the range of expectations, but I emphasize that many variables--even kettle size and manufacturer--come into play.

. . . already looking forward to 2012 (when I probably will NOT make another page).