|

Sugars

In the end, our cane mills are

about producing syrup. Sugars are the principal

ingredients by weight of syrup and confer protection

against spoilage, provide sweetness and body, and

contribute to color if caramelized. Therefore, sugars

merit some mention on this site. First, a general

description of carbohydrates is given. Second, relevant

carbohydrates are described. Third, the conversion of

selected carbohydrates is outlined. Finally, why this

matters to syrup makers is addressed.

Sugars are ubiquitous, diverse,

and abundant in plants, where they serve a myriad of

functions. The simplest of sugars are strings of 3 to 7

carbon atoms. Carbon forms 4 bonds, and the two bonds

remaining (after the formation of bonds with neighboring

carbons) are used to bond with a hydrogen atom on one

"side" and a hydroxyl (OH) moiety on the other.

Simple sugars, therefore, are characterized as having the

ratio of C:H:O = 1:2:1; in short, sugars are

carbohydrates. In the following narrative, I have placed

in bold the main carbohydrates that syrup makers are

concerned with. Glucose (= dextrose),

fructose (= levulose, fruit sugar), and sucrose (=

table sugar, cane sugar, beet sugar) are the main sugars

in cane juice, and starch is the starting point for

making corn syrup (which is blended with cane syrup by

some syrup makers).

Glucose and fructose have six

carbon atoms. Because each of the carbon atoms along the

string can have the H on the "left" or on the

"right" if a flat projection of the string is

made, many different sugars have six carbons, and, of

course, the same goes for sugars of other sizes.

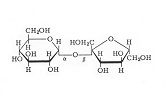

Simple sugars can linked together

to form larger molecules, such as sucrose. Note that sucrose is made from one glucose

molecule (the six-membered ring on the left) joined to a

fructose molecule. This figure also makes it easy to

visualize, as discussed above, how so many different

sugars can result simply by "flipping" the H and

the OH. Lactose (milk sugar) and maltose (discussed

later) are other examples of sugars that are formed from 2

units of 6-carbon sugars. You have probably noticed that

the trivial name of many sugars ends in -ose. Note that sucrose is made from one glucose

molecule (the six-membered ring on the left) joined to a

fructose molecule. This figure also makes it easy to

visualize, as discussed above, how so many different

sugars can result simply by "flipping" the H and

the OH. Lactose (milk sugar) and maltose (discussed

later) are other examples of sugars that are formed from 2

units of 6-carbon sugars. You have probably noticed that

the trivial name of many sugars ends in -ose.

Finally, very large carbohydrates

can be made by linking up to tens of thousands of simple

sugars to form long chains. Cellulose-cotton fiber is

almost pure cellulose-is an extremely abundant resource

and is used to make a variety of products such as paper

and plastics. Cellulose is a chain of glucose molecules

joined from the # 1 carbon on one to the # 4 carbon on the

next. Starch is another large carbohydrate made

exclusively from glucose. Starch consists of two kinds of

chains, though. One kind of chain (amylose) is linear

(again, the # 1 and # 4 are linked to form the chain). The

other kind of chain (amylopectin) has a 1>4 backbone,

but also has branches; amylopectin is very similar to

glycogen, which is the main readily available food reserve

stored in animals ranging from oysters to humans.

Two important points arise. The

physical and biological properties of apparently very

similar carbohydrates are vastly different. Take cellulose

and amylose from the preceding paragraph. Both are simply

chains of glucose units connected between the #1 and # 4

carbons. However, the orientation of the connecting bond

is different. Cellulose is very strong with a tensile

strength exceeding steel; starch has no strength. Starch

forms a gel in hot water, as when we make gravy; cellulose

is unphased by water, as we observe each time we wash

cotton clothes. Starch from wheat, rice, and corn are the

foundation of a good diet; we cannot digest cellulose.

Sucrose and starch can be broken

down using simple chemical means. Sucrose is broken down

into glucose and fructose by heating with acid. Starch is

also broken down into fragments by acid treatment;

depending on the duration, the strength of the acid and

the temperature, breakdown can be complete, all the way to

individual glucose units. Less complete breakdown of

starch yields, among other products of various lengths,

maltose (a fragment of two glucose units). Some types of

corn syrup are prepared by partial or complete acid

hydrolysis of corn starch. There are many different corn

syrup formulations. I chromatographed one source of corn

syrup used by many syrup makers in South Georgia, and it

was pure glucose. One the other hand, I chromatographed a

sample of syrup blend produced in South Georgia from a

different brand of corn syrup and it could not have been

pure glucose.

Carbohydrates can be converted

from one to another using enzymes (proteins that

specifically speed certain reactions.) A commonly used

enzyme is an invertase obtained from yeast. This enzyme

catalyzes the breakdown of sucrose into glucose and

fructose. (Glucose and fructose are thus invert sugars

because a physical property, rotation of plane-polarized

light, has been inverted [changed from plus to minus] by

the conversion of sucrose to the two 6-carbon sugars). If

the treatment is too short or if the conditions (e.g.,

amount of invertase) are not optimum, all the sucrose may

not be broken down. A second commonly used enzyme is one

of the amylases, which partially break down starch.

Amylases are used to manufacture some corn syrups and to

prevent gelling of sorghum syrup. Finally, another enzyme,

an isomerase, converts a portion of glucose to fructose.

Use of this enzyme permits the production of High-Fructose

Corn Syrup (after the starch has been converted to

glucose). Corn syrup is, of course, a cheap sweetner and

various formulations find their way into many foods such

as breakfast cereals, canned fruit, ketchup, soft drinks .

. . . As you have noticed, the trivial names of enzymes

end in -ase.

What does all this mean to a

syrup maker?

- Sugaring. Of the three

sugars in cane juice, sucrose is the least soluble

(i.e., syrup will "hold" less sucrose before

it forms crystals). Although some sugaring is

acceptable, it has two drawbacks (esthetics to some

consumers and potential spoilage of the remainder of

the syrup). Fortunately for the syrup maker, some

sucrose is chemically degraded to glucose and fructose

by heating because the juice is slightly acidic (pH ~

5.2) [see section above]. (An early extension bulletin

indicated that the longer heating time in kettles is

an advantage because the syrup contains less sucrose,

if all else is equal.) There are three remedies for

sugaring under the control of the syrup maker. First,

he or she can choose a variety of cane

that is less likely to form sugar in syrup. This is a very

effective strategy to produce excellent excellent

syrup. Second, he or she can add corn syrup to

the sugar-cane syrup, effectively diluting the

sucrose. Many syrup makers opt for this choice.

Whether to blend or not to blend is a matter of

personal preference, of course, and some prefer the

milder taste of the blend anyhow. Third, and finally,

the sucrose content of the syrup can be diminished by

the use of invertase (see Walton CF, EK Ventre 1935

How to prevent sugaring of sugarcane sirup. USDA

Circular). Walton and Ventre suggested taking the

juice to semi-syrup (20 º Baumé) before treatment.

As I understand it, invertase is considered a

"processing aid," not an ingredient, and

therefore does not need to be listed on the label.

Fructose is the most soluble of

the three sugars and is often chosen in food manufacture

for that reason (e.g., to prevent "sandiness" in

ice cream).

Interestingly, honey bees are

faced with the same problem as syrup makers. Nectar, like

cane juice, is mostly sucrose, glucose, and fructose.

Honey bees inject invertase into the nectar as it is

converted to honey. Thus, honey is mainly glucose and

fructose. Even so, some nectars, like that produced by the

mustard family, contain so much glucose that the honey

crystallizes quickly. On the other hand, tupelo nectar has

so much fructose that honey produced from it never

crystallizes.

-

Spoilage. Of course, the first

line of defense against spoilage is sterilization. A

second potential line is the addition of a

"preservative" such as benzoate. Again, this is

a matter of personal preference, but note that we accept

benzoate in products such as soft drinks. However, the

sugar composition may also play a role. A primary

historical means of preventing the growth of spoilage

organisms is to deny the organisms adequate water. This

goal is accomplished directly by drying the product such

as fruit slices or by "drawing" the water out

with usually salt. The relevant comparative

physical-chemical parameter to measure concentration in

this context is osmolality (osm; not osmolarity), which in

this case is the ratio of sugar molecules to water

molecules. What all this means theoretically is that for a

syrup of given sugar content (weight of sugar per volume

of syrup), a sucrose syrup would be the easiest for the

spoilage organism to thrive in.

Another property of a solution

that depends on osmolality is elevation of boiling point.

For a typical cane syrup, this value is about 12-13 º F

above the boiling point of water, or about 225 º F along

the coastal areas. As indicated in the discussion above,

this value will depend on which sugar (and other components plus deviations from

ideality) in the syrup predominates. (If sucrose

predominates, a lower boiling point would be expected, and

if the 6-C sugars predominate, a higher boiling point

would be expected.) As a general rule, thermometers, which

provide a continuous reading, are used in evaporators

whereas hydrometers are used in kettles, as discussed

below.

-

Thickness. The viscosity, or

resistance to flow, comes into play in two different ways.

First, some syrup makers rely on viscosity (i.e., flaking

off a dipper) to determine when the syrup is finished.

Second, some people have a preference for thicker or

thinner syrups. The least viscose sugar is fructose, with

glucose being slightly more viscose. Sucrose is, by far,

the most viscose (the relative viscosity at room

temperature is almost twice as high for sucrose).

Ironically, a syrup made of sucrose will be thicker than a

syrup made of fructose (or glucose) even when the latter

contains more sugar by weight! These facts, along with the

sharp temperature dependence of viscosity, explain the

difficulty of judging when the syrup is done by using

"flaking." On the other hand, the densities of

solutions made from different sugars at the same

concentration (weight per volume) vary by less than 1 %,

attesting to the utility of a hydrometer. Density, like

viscosity, is affected by temperature, however. For

example, a desirable density for finished cane syrup is

38.5 to 39 º Baumé at 70º F. This same syrup would test

at 34.5 º Baumé at 210 ºF. (Thanks to McCalip and

Walton for these figures from an article in USDA Bulletin

1370, 1925).

-

Sweetness. Fructose is the

sweetest.

|